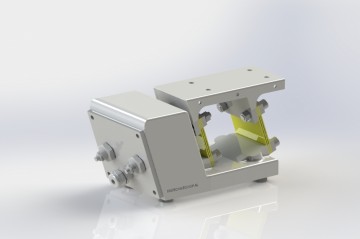

LEX3 - Vibrating magnet Tuxel (food industry)

LEX 3 - TUXEL (vibrating magnet)

You can use an Electromagnetic drive to set your vibrating chute into vibration.

The drives of the type LEX of the brand Tuxel are especially intended for the 'smaller' vibrating chutes. (Width up to 400 mm; Length up to 750 mm).

Your material is transported forward by means of jumps.

Characteristics for the electromagnetic vibrators of Tuxel are:

- SUITABLE FOR THE FOOD INDUSTRY

-

The product flow can be infinitely adjusted, even during operation.

-

High transport capacity with small dimensions.

-

Immediately after switching on, the vibrating magnet operates at maximum capacity and stops almost immediately when switched off.

-

Practically maintenance-free, negligible wear.

-

Noiseless.

The LEX-3 from Tuxel is suitable for a vibrating chute with a weight of approximately 7.5 kG.

(the trough that you can place on top of it may therefore weigh a maximum of approximately 7.5 kG.)

The dimensions of the trough may be approximately 700x200x65 mm (LxWxH)

For the dimensioned drawing of the drive : CLICK HERE

The operating principle of an electromagnetically driven vibrating trough is simple.

A back and forth movement is given to a vibrating trough by means of an electromagnetic vibrating magnet, which is mounted at an angle of about 20˚ on the vibrating trough. At the outward stroke of the vibrating magnet, the product in the vibrating trough is pushed, as it were, diagonally forward and upward. At the incoming stroke of the vibrating magnet, the product falls straight back on the vibrating trough. Because this cycle repeats itself continuously, the product moves in the direction of transport.

When the vibrating magnet is connected to the power supply by means of a Thyristor control, the loose core becomes magnetic. As a result of which the loose core retracts the magnet body, the magnet is released again, causing the leaf spring package to spring the loose core, alujuk and the vibrating trough back again. This goes standard with a frequency of 50Hz.

The product moves through the vibrating chute in a jump-shaped manner. The transport speed of the product is determined by the amplitude of the jumps, which can be controlled by means of a thyristor control.

Attention: a thyristor control is always required to control a vibrating magnet.

Of course the Vibration Technology Shop will supply you with these too, we have several models in our online store.